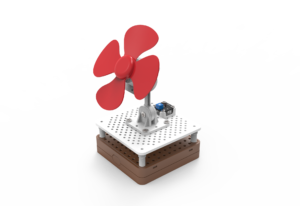

Temperature controlled fan

Pulse width modulation (PWM), or pulse-duration modulation (PDM), is a method of reducing the average power delivered by an electrical signal, by effectively chopping it up into discrete parts. The average value of voltage (and current) fed to the load is controlled by turning the switch between supply and load on and off at a fast rate. The longer the switch is on compared to the off periods, the higher the total power supplied to the load. Along with MPPT maximum power point tracking, it is one of the primary methods of reducing the output of solar panels to that which can be utilized by a battery.[1] PWM is particularly suited for running inertial loads such as motors, which are not as easily affected by this discrete switching, because they have inertia to react slow. The PWM switching frequency has to be high enough not to affect the load, which is to say that the resultant waveform perceived by the load must be as smooth as possible.

The rate (or frequency) at which the power supply must switch can vary greatly depending on load and application. For example, switching has to be done several times a minute in an electric stove; 120 Hz in a lamp dimmer; between a few kilohertz (kHz) and tens of kHz for a motor drive; and well into the tens or hundreds of kHz in audio amplifiers and computer power supplies. The main advantage of PWM is that power loss in the switching devices is very low. When a switch is off there is practically no current, and when it is on and power is being transferred to the load, there is almost no voltage drop across the switch. Power loss, being the product of voltage and current, is thus in both cases close to zero. PWM also works well with digital controls, which, because of their on/off nature, can easily set the needed duty cycle. PWM has also been used in certain communication systems where its duty cycle has been used to convey information over a communications channel.

PWM is also used often with computer fans.